How to: Build a Simple DIY Pegboard Shelf

I love pegboard. I love organizing my workshop with it, I love using it in our office, I think it’s cool when people do the Julia Childs-style pegboard pot rack thing…and I even like seeing it in store aisles, and noting all the clever and and adaptable industrial design things used to display items.

But…But! While pegboard is amazing for hanging stuff neatly on a grid, it does absolutely nothing for items without a hole in them. And there are plenty of those used-on-every-project type tools that it simply can’t handle: glue bottles, drill bits, paint and putty, and most significant to me, a tape measure. I have three or four of them, all basically identical, and I use them all on nearly every project because there’s no obvious place to store them on my pegboard in between making measurements, and they get set down in all kinds of places.

So, I came up with a solution to create very affordable, very customizable DIY pegboard shelves that integrate into any pegboard system and can be made in just a few minutes. They’re just as moveable as normal hooks, so you wont have to drill any holes in your pegboard, yet they still can support a surprising amount of weight across their length.

The system is based on two key materials: 3/4″ thick select grade pine, and square bend hooks. The 3/4″ pine is sold as a 1×4, 1×6, 1×8 etc in the lumber section, and the L-shaped hooks can be found with the eye bolts and other hooks in the hardware aisle.

The are two important things to keep in mind when making this style of shelf:

- It’s best to keep things to whole inch increments, at least for the width – the part that will butt up against the pegboard. Pegboard holes are 1″ on center, and it’s easiest just to consider the shelves as taking up a certain number of hole real estate, so they don’t interfere with more spots than necessary. It’s also wise to think of these as long rather than deep shelves. Pegboard is a mostly vertical system that allows you to use your wall space, not the floor space, so I’d recommend keeping these to no more than 6″ deep.

- In order for the shelves to be installed tight and flush against the pegboard, you need to knock down the back top edge so that you can tilt the shelf to install it with the hooks. You can do this easily with some medium grit sandpaper, a knife, a hand plane, or a router.

More on both below.

The assembly process is super simple.

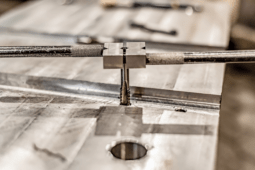

- Measure out your hook spacing on the back. Since pegboard holes are 1″ on center, as long as your holes are spaced at a whole inch length, you’ll be good to go.

- Make a mark at least 1 1/2″ inches from either side, doing your best to keep them on the same center line.

- Drill a pilot hole for the square bend hook. I used a 3/32 drill bit for a #10 hook.

- Add the hook to each hole, making sure it’s an equal number of turns from the back so that it’s evenly spaced against the shelf. Obviously, both hook ends will need to be facing up towards the knocked-down edge.

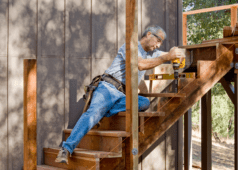

The hooks can be a little tough to drive with just your fingers, so I like to grab them with a pair of pliers, and then spin the wood to drive the threads into the shelf.

Then, attach it to the shelf. You can see how the rounded over or chamfered edge is important to get a tight fit here. It allows the hooks to sit just the pegboard’s thickness (usually 1/4″ or 3/16″) away from the shelf, and still be able to attach it.

And… you’re done!

That’s the basic, use-a-scrap-piece-of-wood-and-some-hardware system. It works great for small, flat items, and can easily be integrated between similar tools that hang on hooks.

For an even stronger, more versatile shelf, you can add a bottom support that will handle much more weight. The idea is basically the same:

Cut a shelf to length, then add a slightly shorter and thinner bottom rail. Here, I cut the shelf to 18×5″ and the bottom piece to 16″ x 3 1/4″, creating a total height of 4″, or four pegboard holes. Attach with a butt joint, and drill and sink screws to hold everything in place.

Since I have a router, I used a chamfer bit around the whole top, knocking down the top edge for installation, and to add a more finished look.

You could even add small hooks to the bottom support for even more versatile storage options.

I plan to use this technique to create even more workshop storage solutions. Let me know what else one could make with this idea in the comments below.

This ManMade post was originally published in September 2014. We’re sharing it again cause it’s time to get that workspace organized!