How to (Safely) Age and Antique Hardware for Your Woodworking Projects

Let's face it: modern hardware leaves a lot to be desired. Sure, it's inexpensive and abundant, but visually, it looks…well, cheap. No character. You spend weeks on a project, choosing wood grain carefully, sanding and planing to a glass smooth finish, and then you're forced to add some blindingly shiny yellow brass or bright blue metal to finish your project.

Of course, there are high-end hardware makers out there producing specialty hinges and components for period furniture, but I wanted a less expensive way to transform general home center hardware into something I actually want to use on my projects.

So, I called my dad.

See, my dad taught high school chemistry for thirty-six years, and he knows his stuff. Sure, that means when we were kids he would literally say things like “pass the sodium chloride” and “is it clear or colorless,” but it also means he can help you find cool, science-based ways to hack everyday life.

So, I asked for his help in stripping the (visually) harsh zinc coating on modern bolts, screws, hinges, etc. “Sure,” he said. “you can use hydrochloric acid or sodium hydroxide, which is lye.” I, of course, know both of those are pretty intense substances, and while they might work, would take a little work to procure at my local neighborhood hardware store, and are quite harsh to use and require proper disposal.

“Anything else? Something a little easier to work with,” I asked. “Of course. Just use tricarboxylic acid.” I looked it up. Boom – citric acid.

Of course, you know citric acid. You ate it as a kid – it's present in all kinds of candy and drink mixes. That Lik-a-Maid stuff in the envelopes with the white chalky sticks is basically just citric acid with sugar added and some flavorings. (Seriously, taste it; it'll make you feel eight years old again.) And it's completely safe to touch with your bare hands, and you can just pour it down the kitchen sink when you're done.

So, I ordered some on Amazon, and got to work.

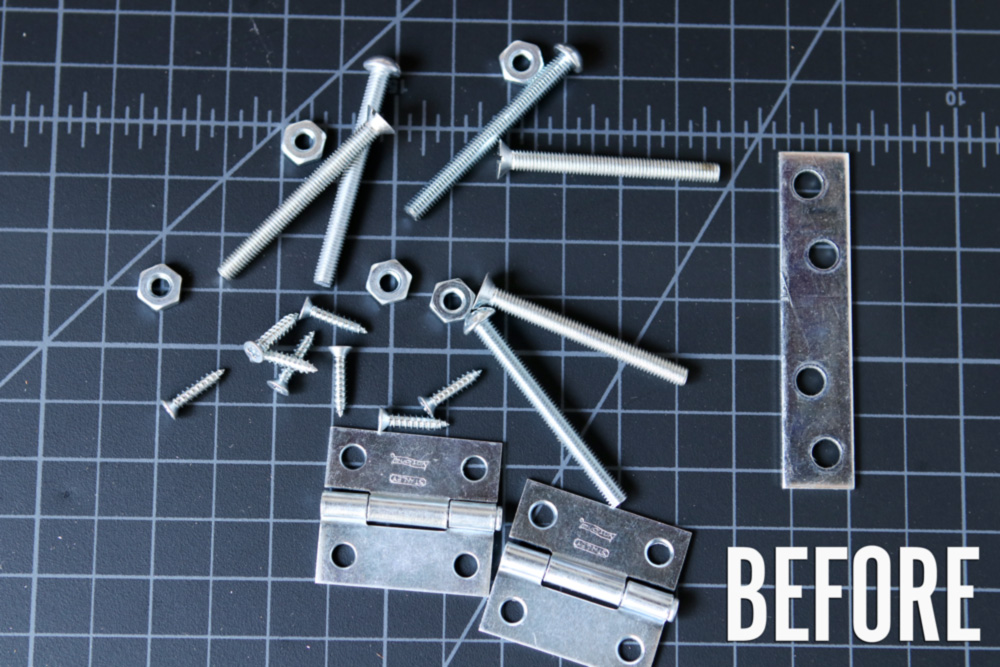

Okay, so here's what you need: citric acid, water, a plastic tub or bucket, and some sort of machine oil. That's it, and it only takes five minutes of active work.

Begin by placing your hardware in the tub. Add some citric acid. How much? I don't know what the perfect ratio is, but I did six tablespoons, and it was perfect. I suggest you start there, and then add more if you need it.

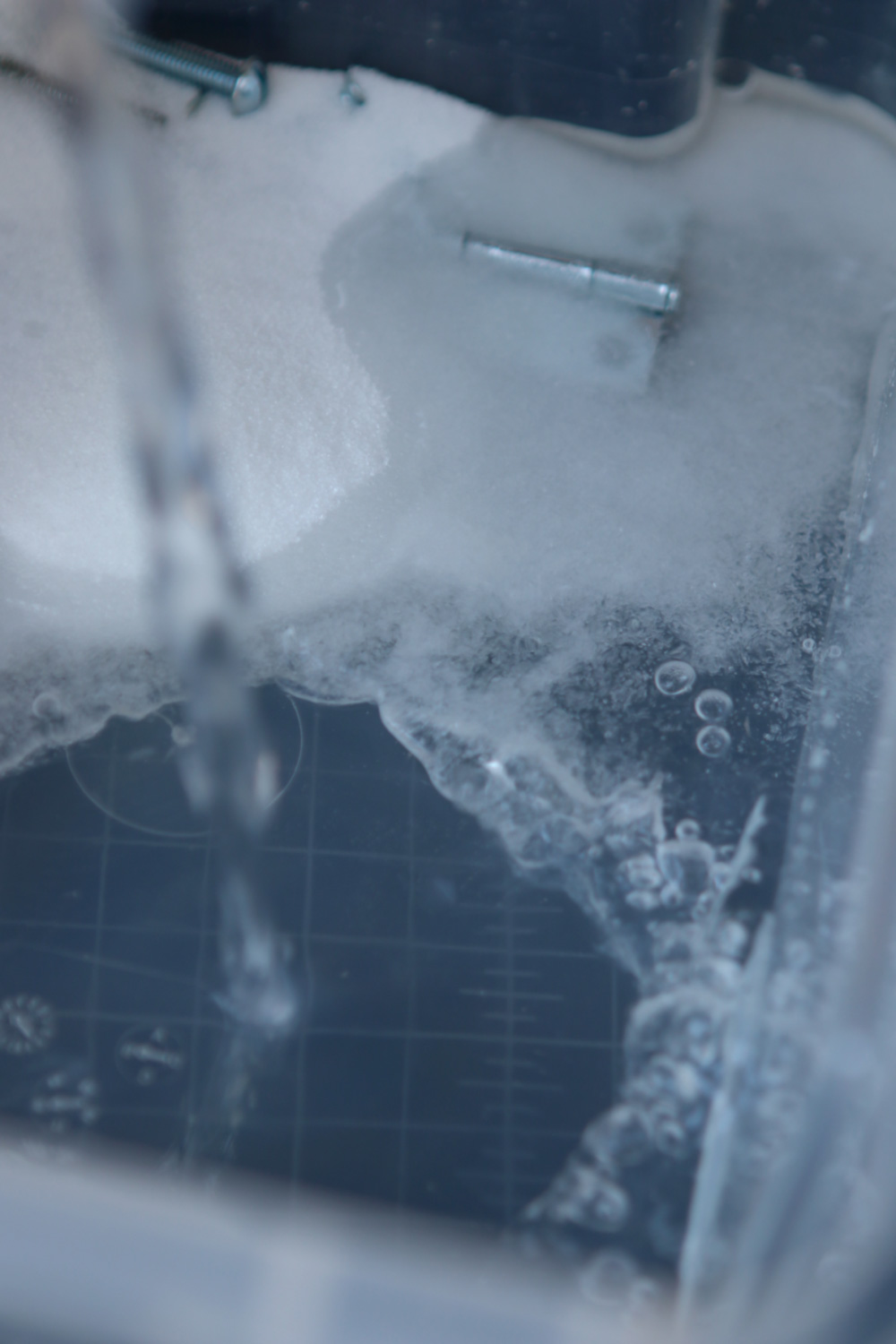

Then, pour in enough water to cover the hardware, plus a little extra. About an inch worked great for me. Stir to dissolve all the solids into the water.

After two or three minutes, you'll start to see bubbles forming around the hardware. This means it's working! If you don't see any reaction after ten minute, add a bit more citric acid to the solution.

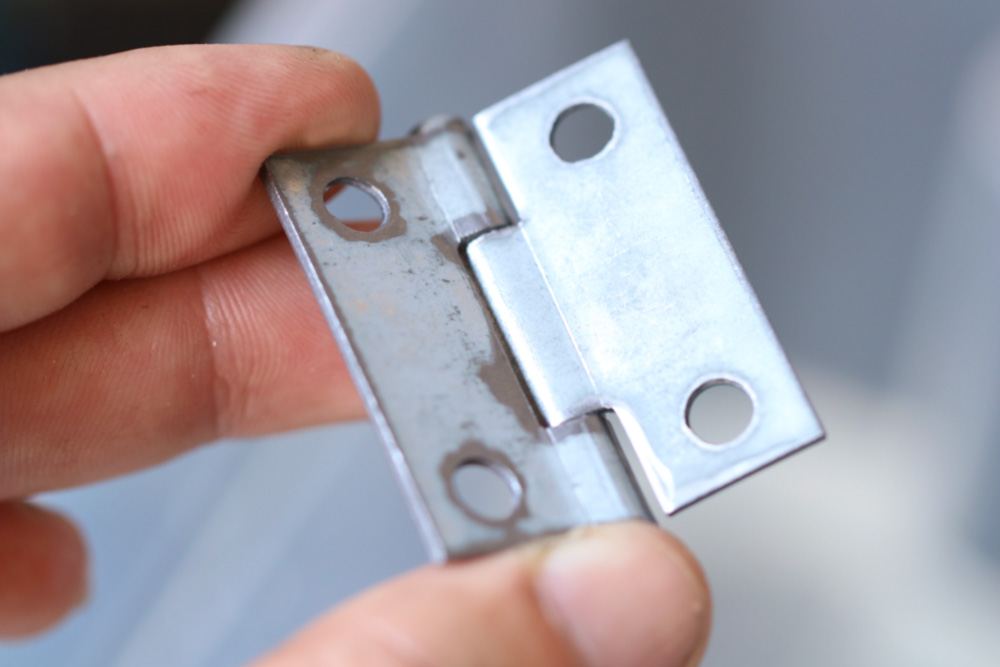

Then, just wait. Screws, bolts, and nuts will be done in just a few minutes. Hinges and plates, etc, will take a bit longer to cover the surface area. Here, I pulled out a hinge after about twelve minutes. The acid worked on the first side, and you can see it starting to react around the holes and gaps on the second. Give any flat pieces a flip to make sure both sides get affected equally.

Once the pieces have a uniform surface and a color you like, take them out of the solution and rinse them off with clean water. You can dump the citric acid water down the sink; just follow it up with some clean water to flush it down.

Of course, that zinc was there for a reason – to prevent the steel from rusting. So, you'll need to cover the hardware in with protective oil. You can really use anything, but the spray straw on a can of WD-40 makes it super easy to apply.

Of course, that zinc was there for a reason – to prevent the steel from rusting. So, you'll need to cover the hardware in with protective oil. You can really use anything, but the spray straw on a can of WD-40 makes it super easy to apply.

Pretty cool, right. Not only does the color darken, but the way the piece reflects light totally changes as well. No more harsh, brittle tones, just a perfectly “aged” vibe. I love the look, and plan to employ this technique as often as possible.

Like this post? Please share it with others on Pinterest.