How to Bend Wood Without Breaking It

Bending wood is a fascinating and essential technique used in woodworking projects ranging from furniture making to crafting intricate designs. However, achieving smooth curves without snapping or cracking the wood can be challenging. By understanding the right techniques and methods, you can master this art while preserving the wood’s integrity. This guide explores practical tips to help you bend wood successfully, ensuring your projects are both functional and beautiful.

Understanding Wood Flexibility

Not all types of wood are created equal when it comes to bending. Hardwoods like oak and ash are known for their flexibility, while softer woods like pine can be more brittle. It’s crucial to choose the right type of wood for your project based on its bending properties.

Another key factor in wood flexibility is moisture content. Wood with higher moisture levels tends to bend more easily, as the added water softens its fibers. Properly conditioning your wood before bending can make the process significantly smoother.

Preparing Your Wood for Bending

Preparation is a critical step in bending wood. Start by soaking the wood in water or steaming it to increase its pliability. This process allows the fibers to become more elastic and reduces the risk of cracking.

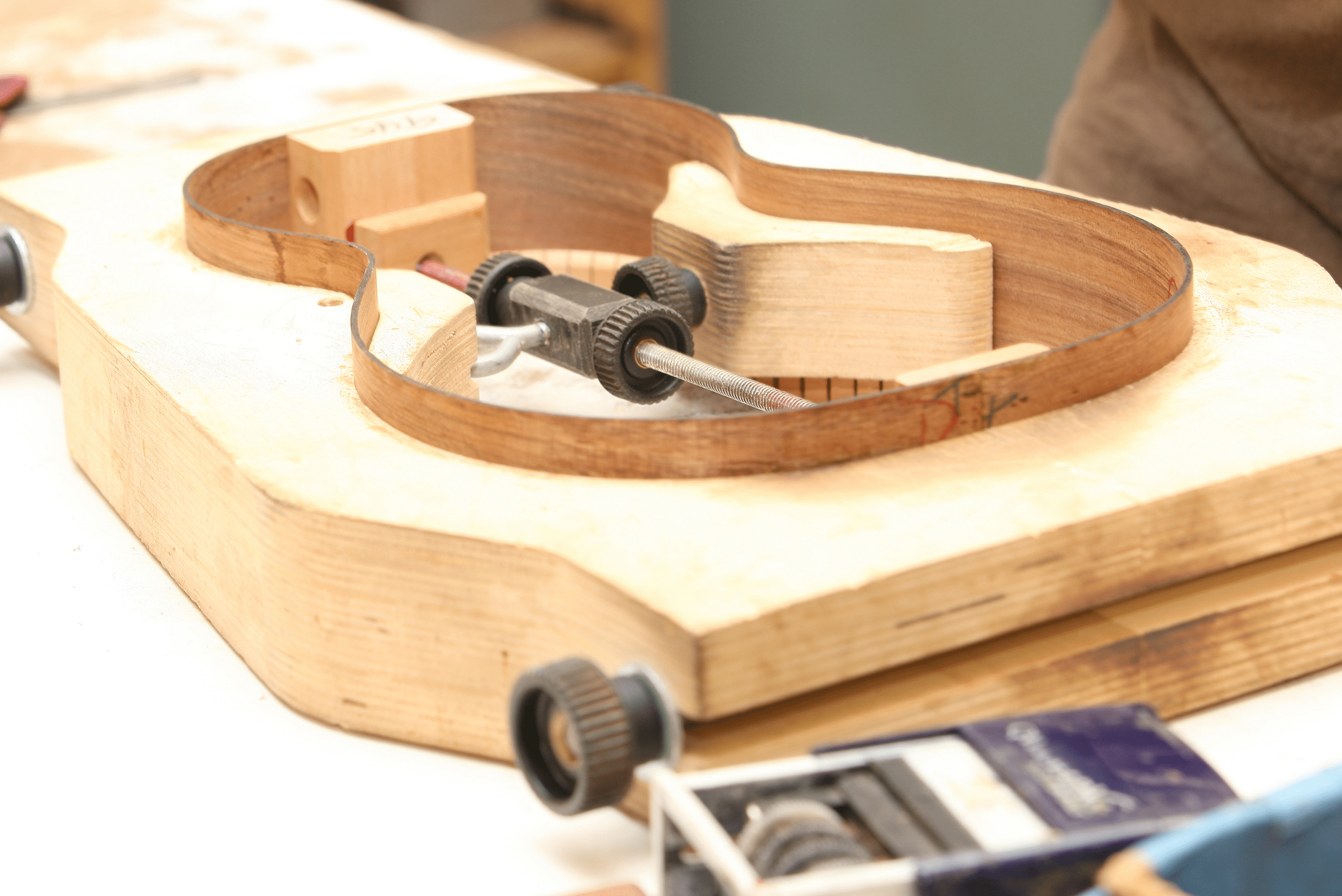

After soaking or steaming, clamp the wood securely into a mold or form that matches the desired curve. This ensures the wood retains its shape as it dries and sets, preventing any unwanted warping.

Techniques for Safe Wood Bending

One of the most popular methods for bending wood is steam bending. By exposing wood to steam, you make it flexible enough to shape around a mold. This technique is ideal for creating smooth, gradual curves without damaging the wood.

Another effective method is kerf bending, which involves cutting small notches along the inside of the curve. These notches allow the wood to flex without breaking, making it a great option for tighter curves or complex shapes.

Tools and Equipment You’ll Need

To bend wood successfully, you’ll need the right tools and equipment. A steam box or a large pot can generate the necessary steam to soften the wood. Sturdy clamps will also hold the wood in place while it sets.

For kerf bending, a table saw or circular saw is essential for making precise cuts. Additionally, having a flexible tape measure and a mold or form ensures your project maintains its desired shape during the drying process.

Avoiding Common Mistakes

One common mistake in wood bending is rushing the drying process. Allowing the wood to dry thoroughly while still clamped in its mold is crucial to prevent spring-back, where the wood reverts to its original shape.

Another frequent issue is using wood with existing cracks or defects. Always inspect your wood carefully before starting, as flaws can worsen during bending, leading to breakage or structural weakness in your project.

Related Articles

- Must-Have Jigs You Can Build or Buy to Ensure Woodworking Precision

- The Secret to Perfectly Smooth Wood Every Time

- A Comprehensive Guide to Properly Impregnating Wood to Preserve Wood

Bending wood without breaking it requires a mix of preparation, technique, and patience. By choosing the right wood, using proper methods like steaming or kerfing, and avoiding common mistakes, you can achieve stunning results. Whether you’re a seasoned woodworker or just starting out, mastering this skill opens up endless creative possibilities for your projects.

Ready to start your next project? Join our DIY community to receive tool tips, how-to guides, and exclusive creative insights. Subscribe to the ManMadeDIY newsletter now! Click here to unlock a world of hands-on inspiration.