How to Cut Metal Studs: Expert Tips for Precision

If you were to ask someone how to cut metal studs and they gave you a single technique, you need to ask again. Metal studs have many applications in modern construction, making them a versatile choice for an array of projects and applications.

They can be weight-bearing members, meaning they have the strength and structural integrity to be outside studs that hold up a roof. They can also be purely internal, with lightweight capabilities that simply hold drywall and have no structural requirements, or they can be something in between.

Benefits Of Using Metal Studs

Whether internal or external, metal studs are part of the structural skeleton of most new buildings. They have advantages in termite-infested areas since the best efforts by those pesky little insects won’t even mar the finish. They are more fire-resistant than their wooden counterparts, and they last much longer.

But how do you cut them to length when assembling a home or business?

Determine Metal Size and Application

The first step is to determine what type of metal stud you’re dealing with. As with dimensional lumber, metal studs come in sizes similar to 2×3, 2×4, 2×6, and 2×8 lumber. Selecting the right dimension metal stud allows you to use similar-sized wooden lumber along the same wall in mixed exterior settings and if you need to create a custom wooden frame within a metal wall for a door or window.

Metal studs come in various size gauges. The higher the number, the lighter the metal in the stud. Common studs range from heavy-duty 12-gauge metal to light-duty 20-gauge metal members.

Cutting Light-Gauge Metal Studs

Studs can be made of unfinished steel, galvanized steel, or lightweight sheets of galvanized steel that are often mistakenly called tin. However, cutting the various gauges requires different techniques.

Starting with the lightest gauge, you can cut, trim, or adapt these studs with a pair of metal shearers or side cutters. Aviation snips work great with lighter studs, too.

Cutting Heavy-Gauge Metal Studs

When starting to work with heavier studs, those aviation snips won’t cut it (literally) anymore.

You’ll need to move to a saw or angle grinder, which are available in an array of configurations and offer many different blade types. Also, you can use a cutting torch if you have one available.

Angle Grinder

An angle grinder is great at cutting metal studs and smoothing out rough edges left from cutting.

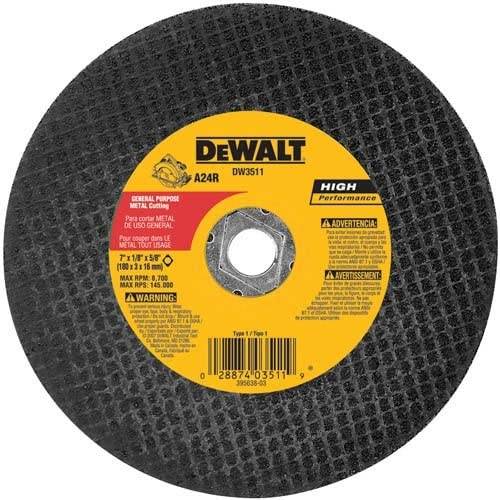

You can find an array of blades when using an angle grinder, letting you cut heavy-duty gauge metal studs with ease.

Chop Saw or Miter Saw

The best cuts are made with a chop or miter saw equipped with an abrasive blade. These blades are specially designed to cut light metal.

You can also use an abrasive blade in a circular saw to cut metal studs.

Sawzall

Another technique is to use a heavily toothed, bimetal blade in a Sawzall.

You will find that Sawzalls are versatile, especially if you have a battery-powered tool rather than a corded one.

Cutting Torch

For the heaviest structural steel, sometimes the best tool aside from an industrial-grade cutoff saw is a cutting torch.

Mark a line with a piece of chalk on all four faces of the metal, then follow the lines with a cutting torch. You may have to grind the newly cut face if you’ve wobbled a bit, but if you are careful, your fire-cut metal stud will work just fine. Don’t try the cutting torch with lighter-grade studs.