Impact Wrench vs Impact Driver: Key Differences

Understanding the differences between impact wrenches and impact drivers is essential for selecting the right tool for your specific applications. We’ll get into the key disparities between these two tools and provide insights into their applications, features, and benefits, helping you make an informed decision that aligns with your project requirements and preferences.

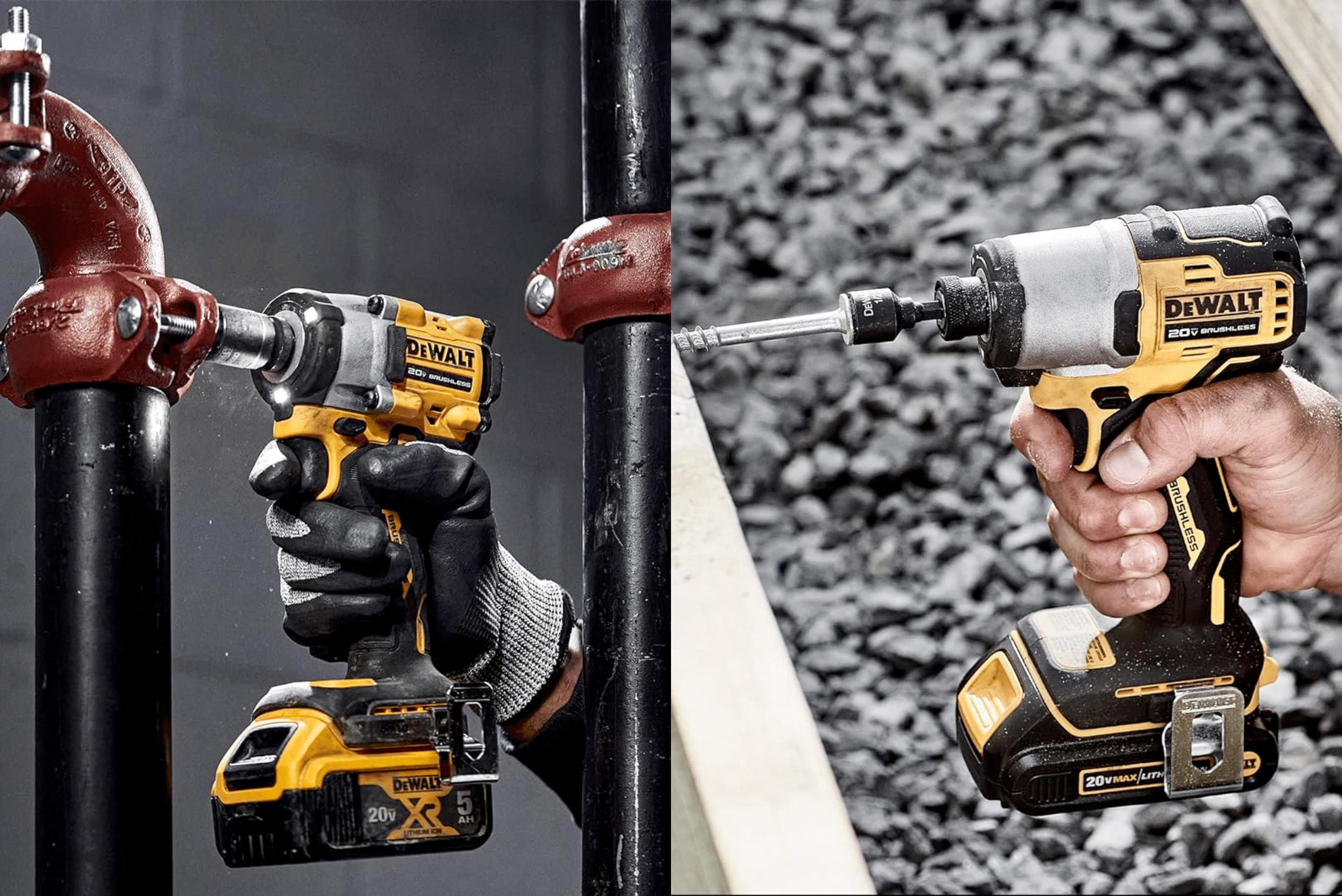

Impact Wrenches: A Closer Look

An impact wrench is a robust tool engineered to deliver high torque output for heavy-duty fastening and loosening tasks. Unlike conventional wrenches, impact wrenches employ a rotational hammering mechanism to generate quick force, making them indispensable in automotive, construction, and industrial applications.

Their ability to handle large bolts and nuts with ease makes them ideal for professional settings and DIY projects that require significant force. However, you will find corded, cordless, and pneumatic options, with models varying in power output and size to meet a wide array of fastening or loosening tasks.

Insight into Impact Drivers

Impact drivers are compact, lightweight tools primarily used for driving screws, nuts, and bolts. Equipped with a unique mechanism that delivers high rotational force, they excel in tasks requiring efficiency and precision. Widely used in woodworking, cabinetry, and general construction projects, impact drivers are valued for their versatility and capability to handle a variety of fastening tasks.

You can find corded impact drivers, although not commonly seen anymore, especially since cordless models are widely available at competitive prices on the market. When shopping for a cordless power tool such as an impact driver, you might want to fork over the extra cost for a model with a brushless motor that will deliver better performance and longevity.

Variances in Design and Functionality

While both impact wrenches and impact drivers utilize impact mechanisms to deliver torque, their design and functionality exhibit significant differences. Impact wrenches are larger and heavier, featuring a square drive anvil that will accept 1/4, 3/8, 1/2, or 3/4 sockets fastening and loosening applications.

Conversely, impact drivers are designed with a hexagonal chuck that accepts screwdriver bits, making them ideal for precise screw and fastener driving. You can equip an impact driver with a variety of hexagonal bits, but it’s not advised to use an adapter for sockets since you will likely experience performance issues or excessive wear on the tool.

Features and Considerations: A Closer Look at Tool Selection

When selecting between an impact wrench and an impact driver, consider specific features aligned with your intended applications. Look for adjustable torque settings, variable speed triggers, and ergonomic designs that enhance user comfort and control.

Additionally, consider the compatibility of the tool with accessories such as impact sockets and screwdriver bits to ensure seamless operation. Although you can buy accessories to cross the functions of these tools, we truly advise that you pick up a high-quality model of each, which will yield you the best value in the long run.

Impact Wrench vs. Impact Driver: Making the Right Choice

Determining whether you need an impact wrench or an impact driver depends on the nature of your projects and the type of fastening and loosening tasks you frequently encounter. Impact wrenches are essential for delivering the necessary torque when working with large bolts, nuts, and lug nuts. Another consideration is the fastener condition since rust can make it tough for anything other than an impact wrench to remove the stubborn bolt or nut.

On the other hand, if your projects involve driving screws into wood, self-tapping screws into sheet metal, or lag bolts into wooden posts, you will likely want to have an impact driver. Don’t attempt to drive a large bolt with an impact driver since it will likely cause the impact driver to run hot while also struggling to perform the task.

Maintenance and Care Tips: Ensuring Longevity

To ensure the longevity and optimal performance of your impact wrench or impact driver, adhere to regular maintenance practices. Keep the tools clean and free of debris, inspect the power cords or batteries for any signs of wear, and lubricate moving parts as recommended by the manufacturer. Proper storage in a dry and secure environment can also prevent damage and extend the lifespan of the tools.

Related Tool Articles:

- Choosing the Right Saw: Breakdown of Different Types

- Hammer Drill vs. Impact Driver: Which is Better?

- Mastering Sawzall: Essential Tips and Techniques

Understanding the differences between impact wrenches and impact drivers is crucial for selecting the right tool for your specific applications. By considering the design, functionality, applications, and safety aspects of these tools, you can make an informed decision that aligns with your project requirements and preferences, ultimately leading to successful outcomes in your professional or DIY endeavors.