What You Need to Know About MDF & Its Uses

If you consider yourself to be handy, particularly in the building of household items, then there is a good chance that you have heard of MDF. Medium-density fiberboard (MDF) has a ton of uses, which is why it is so common.

This is your guide to learning all that there is to know about medium-density fiberboard. From its composition to its uses and more, you will become a master of what MDF is all about.

What is MDF Board?

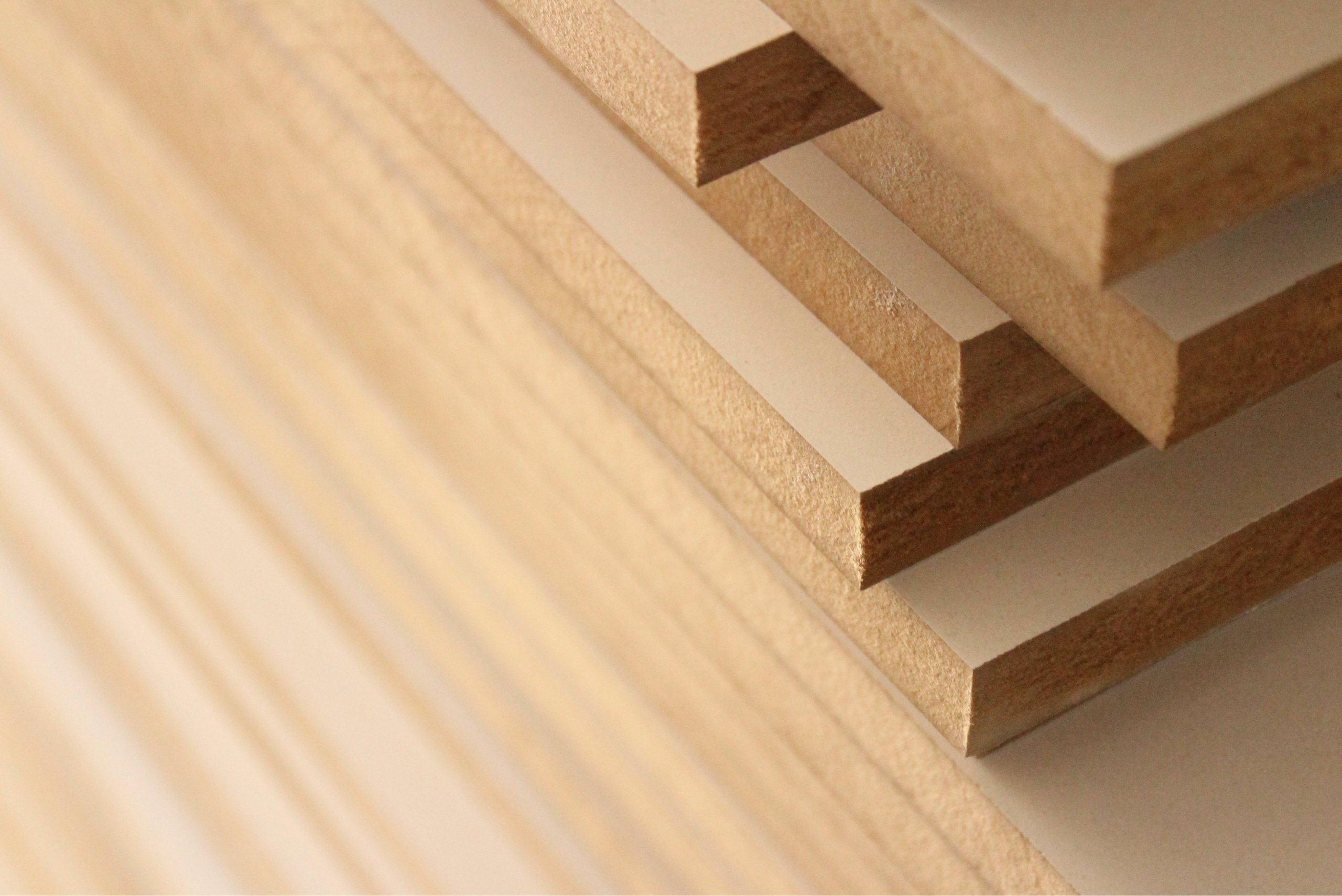

MDF board, or medium-density fiberboard, is a wood material that is prepared through the process of separating hardwood or softwood residuals into wood fibers. This is done through the use of a defibrillator, wax mixing, and the process of forming a panel into a particular shape through the use of high temperatures and pressure.

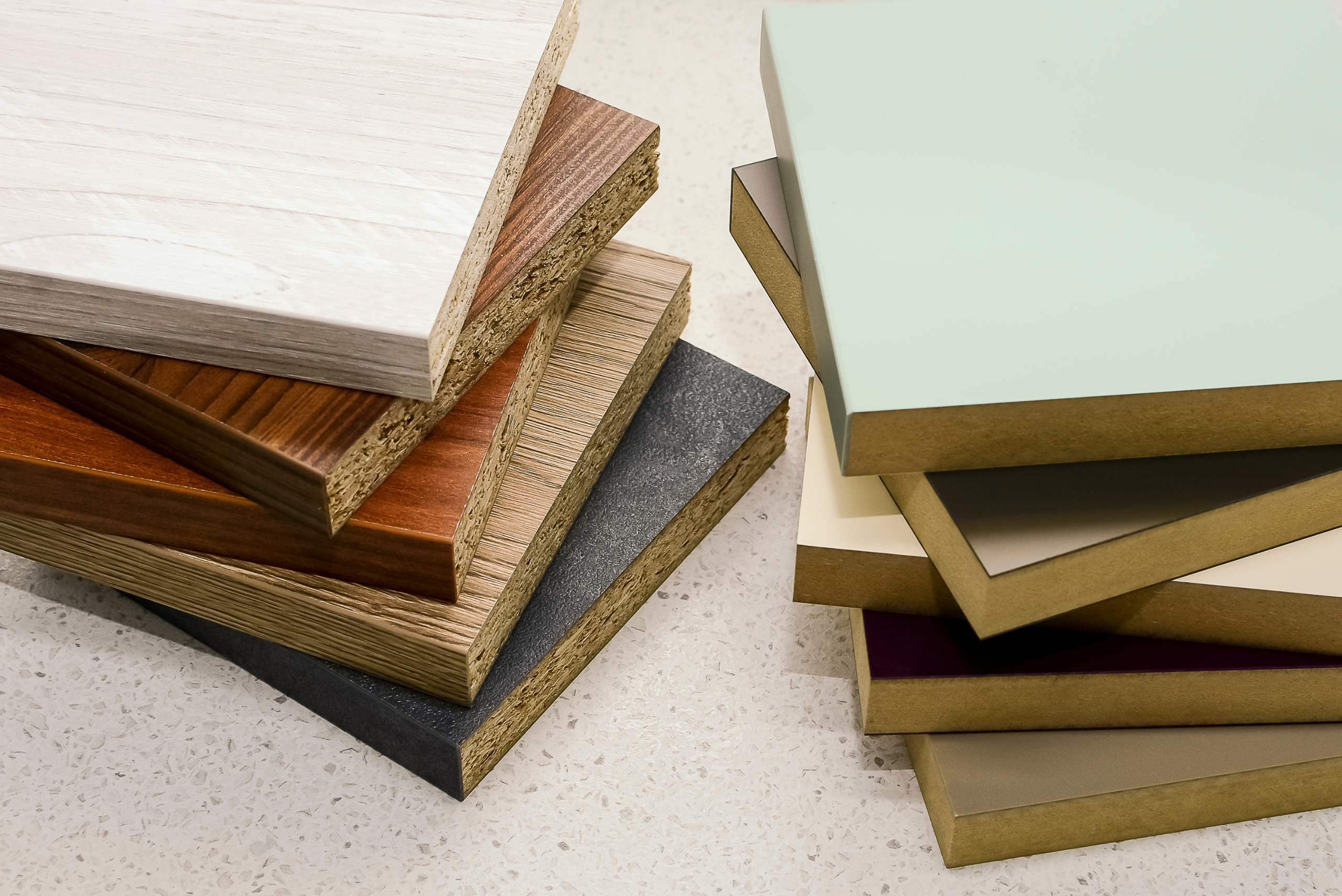

For the most part, MDF is a slightly more dense plywood. It has a composition made up of separated fibers, but it can be utilized in the same way that plywood is applied as a building material. Compared to particleboard, it is a lot tougher and denser.

MDF is considered to be a medium-density fiberboard and is a DIY-friendly sheet material that is typically used for things like molding, furniture, and cabinetry. That is because it is quite cost-effective and versatile as a material. All of which help to make MDF boards quite a popular choice for any number of projects.

The thing to keep in mind is that MDF is generally not used as a finish on its own. It can, however, be finished using a laminate or veneer, which gives the overall impression of a real, high-quality wood finish.

What are the Differences Between MDF and Particle Board?

MDF board and particle board are often times confused or used as one and the same. But there are actually a number of differences between the two that make them substantially different from one another. Let’s take a closer look at the two and see what the major differences are.

Density. MDF board is far superior in terms of density. It has a higher level of density, whereas particleboard is generally a lot less dense, meaning that it can’t hold up over the long term quite as well as MDF.

Look. Particleboard is completely unfinished. It doesn’t have a smooth, shiny surface, so you generally wouldn’t want to use particleboard for finished products. MDF, on the other hand, can have a shine and smoothness to it. This is because the wood grains used are of the same size.

Strength. Particleboard (as we will get to later) is largely popular due to its cost. That said, there are corners cut to keep it cheap and that is in the strength. MDF is generally much stronger than particleboard regardless of the application.

Durability. MDF is a long-lasting, durable material that is used in a number of applications. Particleboard, meanwhile, is generally not going to last all that long before it starts to break down and show wear.

Moisture. Moisture of any kind is likely to warp and eventually destroy particleboard. Unlike particleboard, MDF has more resistance to moisture which makes it more effective for use in both interior and exterior projects.

Weight. Particleboard is quite light and easy to use, another reason why it is commonly chosen for minor projects. MDF, on the other hand, is quite a bit heavier and more versatile than particleboard would be in the same application.

Price. The main reason why people use particleboard in general because it is cost-effective. You can get quite a bit of particleboard for relatively cheap, making it one of the most popular options for most DIYers. MDF board is a bit more expensive than particleboard, but you can expect to get a lot more durability out of your MDF board.

Lifespan. The conditions will largely dictate how long either material will last. MDF can last 10 years or more for both interior or exterior purposes, providing moisture and sound resistance while also holding up against fire. Particleboard, can last just as long provided it is kept under ideal conditions. If it is exposed to moisture or anything that can lead to accelerated wear and tear, you can expect particleboard to wear down far faster.

What are the Pros and Cons of MDF?

When it comes to MDF board, there are more than a few things to like with a few others that you won’t. Let’s take a closer look at the good and the bad of MDF board before you take the next step to buy some for your next project.

The Pros

There are a ton of things worth noting about MDF board. Here are a few of the most notable properties that you should consider with MDF board.

Economical. For a start, it comes at a reasonable cost. Yes, there are other materials out there like particleboard that are cheaper, but they are not of the same quality that MDF board can offer for the price range.

Recyclable. For those who like to use materials that have an eco-consciousness to them, MDF board is made of recycled materials. That means no unneeded waste just to get your next project done, helping to minimize the carbon footprint that we leave behind.

Great for staining. The great thing about MDF is its high versatility from a staining standpoint. It can be painted or shaded in order to give it a more natural look than it would otherwise have. If you want to match up your MDF board project with your home aesthetic, it is easy to do.

No knots. Some types of wood can have kinks or knots, which can give a less than quality look. For those who like a shiny, smooth surface, then MDF board would be the ideal material choice for your home projects.

Insect and chemical resistant. A major factor in choosing the right material for the job has to do with the durability. Being resistant to both chemicals and insects means that it is likely to hold up longer than other materials.

Natural look. Compared to something like particleboard, MDF board has a more natural look to it. It can look like natural wood veneers, for instance, which can give it a higher quality finish than some of the other options out there.

Strength. MDF board is quite dense, flat, stiff, and strong. That means it can hold up to most applications for a long time to come, especially compared to other types of wood (particleboard in particular).

Easy to cut. Finally, another major benefit of MDF board is that it is easily machinable. It can be cut, drilled, and machined without creating any defects because it has no grain to it. Its versatility is unlike any other type of material out there.

The Cons

Though there is a lot to like about MDF board, there are some natural downsides. Of course, you will find the good and the bad in just about any material but knowing both sides of the equation can make a huge difference when you choose your material.

Not as strong as wood. MDF board is effective for most things, but it just is not as durable or strong as wood. If you are building something with the expectation that it will last for 30+ years, then going with a natural wood is probably the better way to go.

Pressure limits. On the same hand, there are also pressure limits when it comes to MDF. Higher levels of pressure can cause MDF to either slash or break accordingly.

Soaks water. If you are going to use MDF for outdoor purposes, it has to be stained or treated to hold up against moisture. MDF naturally soaks in water quicker compared to other types of wood.

Difficult to drive nails or screws. If you are going to be screwing or nailing into MDF, just know that the process is a little more difficult than other types of wood.

Uses VOC. The major unfortunate thing about MDF is that it uses VOC, which can include things like urea-formaldehyde. These chemicals can get into your eyes and lungs, becoming a major irritant as a result.

Tons of dust. Finally, there is the issue of dust when cutting or sanding MDF boards. When you have dust in the air, it can cause irritation and damage to the eyes and lungs, making it difficult to breath.

Properties of MDF Board

The composition of MDF board has changed a little throughout the years. In the past, the raw material used in the composition of MDF was actually wheat that was completely suited for pilot plants. That said, most of the manufacturing of good-quality MDF is through the utilization of binders.

Chemicals like urea melamine-formaldehyde are used to create an effective adhesive combination that helps to give the MDF board a greater overall composition.

Some MDF board products require distinct qualities of both resin as well as wheat straw, though this is called straw medium density fiberboard (SMDF) and is slightly different.

The average board of MDF ranges from 2-35mm in thickness and is generally about 4 feet long. It also has natural properties of elasticity, thickness, water absorption, swelling, modules of rupture and elasticity, and an internal bond strength that is superior to cheaper options like particleboard.

The Uses of MDF Board

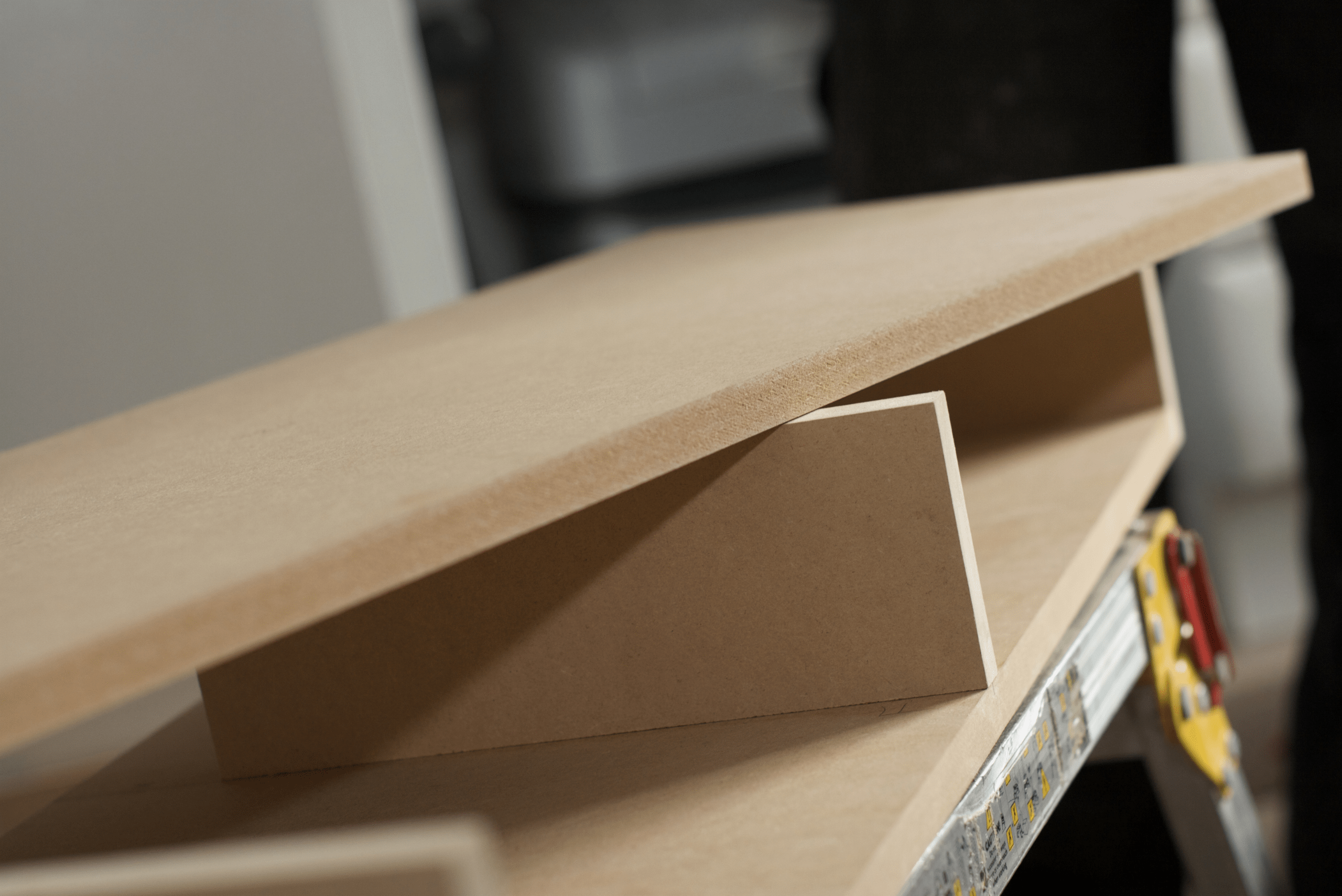

MDF board is very versatile for a few different reasons. It can be shaped, cut, and even painted to create the look that you want to achieve. This is all due to its smooth properties, making it one of the most versatile options out there.

For those reasons and more, it can be used for any number of projects. Here are some of the most common uses for MDF board.

Furniture

Another major use of MDF board is the construction of furniture. There are many DIYers out there who like to build their own furniture of varying styles. MDF board is so versatile that it is even used by furniture companies to create finished furniture products.

Those relatively cheap bookshelves, television stands, shelves, etc. are all made of MDF board. That is because they are proven to be far more economical when compared to pure wooden furniture. Though the latter has a superior quality, the overall quality of MDF is solid enough that it will work for most people, especially at the much lower price tag.

The only caveat with products like that is that they have to be put together and we all know how adventurous that process can be. But if you are a total DIYer, you can build your own custom furniture using MDF if you have the skills and tools.

Roofing

If you don’t get the message that MDF board is quite versatile, here is another thing that can sway your opinion. MDF board is actually used in home roofing systems all the time because it has good weather resistance abilities.

MDF board is proving itself to be a great material when it comes to backing for different roofing types. It can also be used as wall sheathing when it comes to work on the interior of the home. This is partially because MDF board is so flexible and its durability, in both interior and exterior work, is something that will hold up over time.

Cabinetry

One of the most popular uses of MDF board is for cabinetry. It can be used for most interior products, but interior carpentry cabinetry work is right up at the top of the list. The simple fact of the matter is that there are a ton of cabinets out there that are pre-manufactured that are totally comprised of MDF board. They are then covered using a laminated wood to give them the finished look that you see.

There are tons of household uses for MDF cabinetry as well. Kitchen cabinets as well as shelving units can be manufactured using MDF board and then molded to look how you want them to look. Other household uses include door framework, molding work, and even laminated wooden flooring.

It is entirely possible to make the vast majority of your interior look centered around MDF board. When you are looking to take on another project, MDF board is probably the best way to go.

Soundproofing

One of the lesser known facts about MDF board is that it can actually work to be an effective sound barrier for the interior of your home. It can help substantially cut down on the amount of outside noise that permeates your home.

There are even some companies that manufacture speakers that make use of MDF board within their products. That is because MDF board can reduce internal vibration and absorb sound, which can drastically alter the overall quality of the stereo in question.

Because of its sound reduction qualities, it is not uncommon to find MDF boards in newsrooms, offices, and even in building flats in an effort to cut down on outside noise. For those who need quiet spaces or even a sound studio, MDF board would make for an effective material to use.

Vapor Resistance

One of the main concerns in any building construction is keeping unwanted vapors out of the building. What most DIYers don’t realize is that MDF boards can be used as insulation, presenting an obstacle to some of the vapors that face not only commercial buildings, but residential buildings as well.

This specific type of fiberboard is manufactured in a way that it is able to deal with the moisture emitted from those vapors for a very long time. The drying process is also shrinkage-free, which means that the MDF board won’t just shrink after warming and then drying. All without any potential rotting effect to it.

For homes in particular, where keeping moisture out is of the utmost importance, fiberboard can be hugely beneficial. It also helps to keep the home running as efficiently as possible, requiring less heating and reducing your overall electric bill each month. There are a lot of benefits to MDF board, but the ability to keep moisture and vapor out is right up at the top of the list.

Fire Resistance

There are a lot of major benefits to going with MDF board for your next project. But what most people don’t realize is that MDF has exceptional fire protection. That is because it has good quality properties when it comes to fire resistance.

In recent construction in particular, any fire resistant materials are a plus. The need for those materials has grown rapidly in recent years and MDF makes a great choice due to its fire resistance qualities. When you have something constructed from MDF, you can have the peace of mind in knowing that it has the ability to stand up to fire.

How Much Does MDF Board Cost?

Like any other kind of wood, the cost of MDF board can depend on the thickness and type of medium density fiberboard that you choose. The thicker it gets, the more expensive that it will be. There is also the vendor factor, as some will be inherently cheaper or more expensive than others.

Decorative MDF board will cost around $52 per square foot at a thickness ranging from 2mm to 25mm. Laminated medium density fiberboard will run around $42 per square foot for that same 2mm to 25mm thickness.

Laminated medium density fiberboard teakwood is the same price for the same thickness as the laminated MDF. The only one that would be more expensive, aside from decorative medium density fiberboard, is pre-laminated medium density fiberboard.

The short answer to a long question is that you can safely expect to pay anywhere from $40 to $ 60 per square foot for medium density fiberboard.

FAQs

What does MDF mean?

MDF stands for medium density fiberboard. It is a type of wood that is prepared through the breaking down of either hardwood or softwood residuals. Those residuals are then turned into wood fibers, frequently through the use of a defibrillator. They are then combined with wax as well as a resin binder, which is then turned into panels using high pressure and temperature.

Can You Paint MDF?

One of the great things about MDF is that it can be painted. You can use either an acrylic paint or interior latex paint to transform your MDF into the color that you have been looking for.

Is There a Difference Between MDF Wood and MDF Board?

There is no difference, it is just the terminology that is different. MDF wood and MDF boards are created by shattering down hardwood or softwood residuals. They are then shaped into wood fibers using a defibrillator, combining it with a resin binder and some wax in order to add properties into the wood.

What Can MDF Be Used for?

MDF can be used for a lot of different things. Keep in mind that it isn’t often times used as a stand alone finish, but it can be finished using laminate or veneer, which will give off the impression that it is real wood. MDF board is used in furniture, cabinetry, and can even be used in both interior and exterior applications.