Teak Oil vs Tung Oil – Choosing the Right Finish for Wood

When it comes to preserving and enhancing the natural beauty of wood, teak oil, and tung oil stand out as two of the most popular choices among woodworkers, DIY enthusiasts, and professionals alike. Both oils have their unique characteristics, applications, and benefits, making the decision between them more than just a matter of preference.

In this guide, we will get into the heart of the teak oil vs tung oil debate, shedding light on their individual properties, the protection they offer, and how they can transform the appearance of wooden surfaces. Whether you’re undertaking a new project or looking to maintain the luster of your existing wood pieces, understanding the differences between these oils will empower you to make an informed choice that best suits your needs and the demands of your woodwork.

Choosing the Right Wood Finishing Oil

When embarking on a woodworking project, the finish you choose can dramatically affect both the appearance and durability of your piece. Understanding the differences between popular options like teak oil and tung oil is essential. Both oils penetrate deep into the wood, enhancing its grain and natural beauty.

Teak oil, derived mainly from linseed or tung oil mixed with other resins and varnishes, is favored for its relatively easy application and maintenance, making it ideal for outdoor furniture. On the other hand, tung oil, pressed from the seeds of the tung tree, offers a hard, durable finish that resists water and alcohol, perfect for items like countertops and cutting boards.

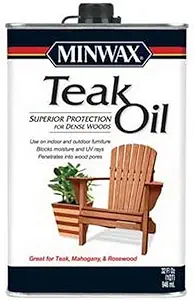

The Basics of Teak Oil

Often chosen for its ease of application and ability to penetrate deeply, teak oil enhances the natural grain and color of wood. This oil is favored for both indoor and outdoor furniture due to its protective qualities. It helps to guard against moisture and UV rays, making it a practical choice for items exposed to the elements. However, teak oil is not without its considerations. While it does provide a robust layer of protection, it needs to be reapplied periodically to maintain its effectiveness.

This maintenance requirement might influence your choice depending on how much time and effort you are willing to invest in upkeep. It’s also worth noting that teak oil can vary in composition, with some products containing additives like varnish or other oils to enhance durability and drying time. Therefore, reading labels and understanding the specific product you’re using is crucial for achieving the best results.

Common Uses in Woodworking

Teak oil is a popular choice among woodworkers and DIY enthusiasts for its ability to enhance and protect hardwoods. Derived primarily from either tung oil or linseed oil, teak oil penetrates deeply into wood, providing a strong barrier against moisture and environmental damage.

This makes it an excellent option for projects that will face exposure to the elements, such as outdoor furniture, decks, and boats. Its ease of application and the warm, rich sheen it imparts on woods like teak, mahogany, and walnut also contribute to its favored status in woodworking projects.

In practical applications, teak oil is often used to finish and maintain wood surfaces that are subject to frequent handling or moisture contact. It dries faster than many other oils, which helps speed up finishing processes without sacrificing durability.

By penetrating the wood, teak oil also helps to highlight the natural grain patterns, enhancing the visual appeal of the wood without the need for complex techniques or additional coatings. Its versatility and protective qualities make it a go-to solution for both novice and experienced woodworkers looking to preserve the beauty and integrity of their wooden creations.

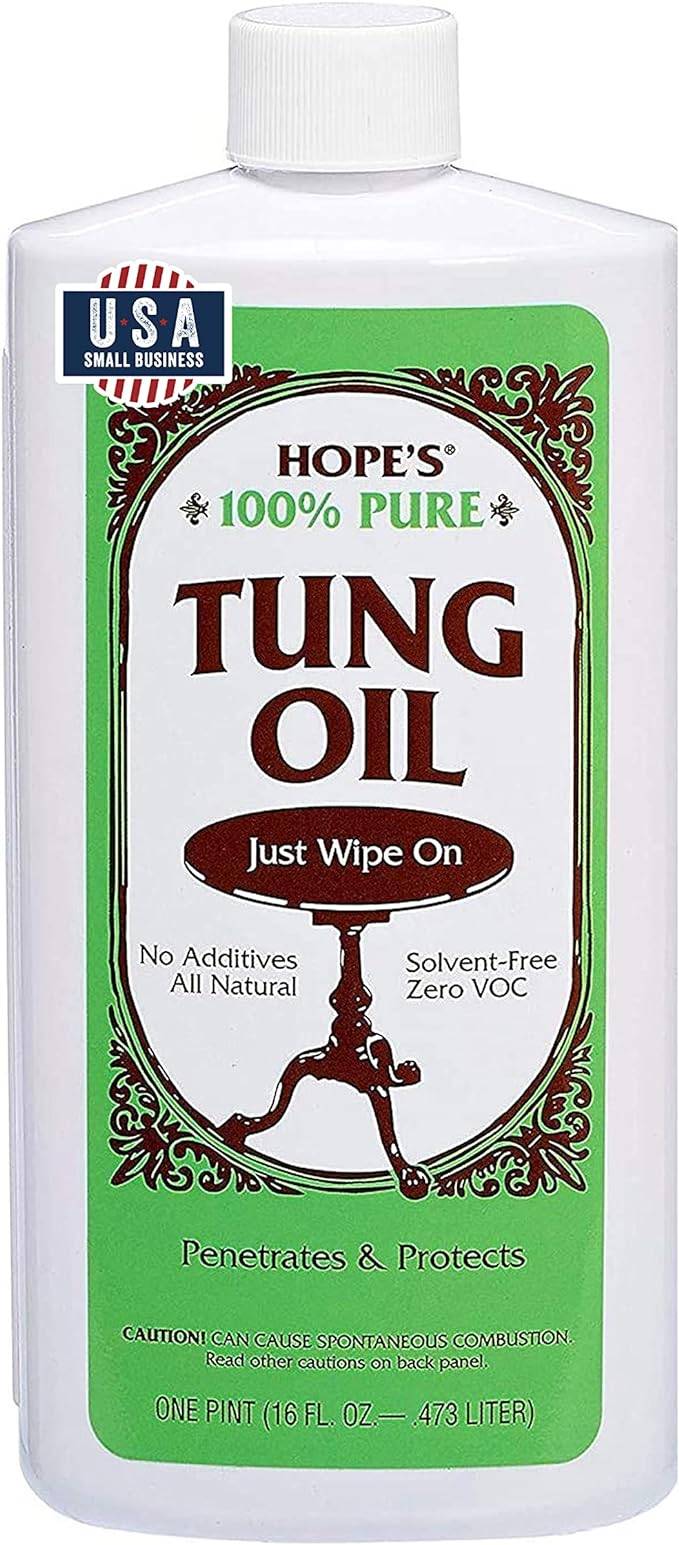

The Basics of Tung Oil

When considering the use of tung oil, it’s essential to grasp its fundamentals to make an informed decision, especially when compared to alternatives like teak oil. Tung oil, derived from the seeds of the tung tree, primarily found in China, has been a trusted resource in wood finishing for centuries.

Its popularity stems from its ability to penetrate deep into the wood fibers, creating a water-resistant barrier that not only enhances the wood’s natural beauty but also provides a robust layer of protection. This characteristic makes tung oil an excellent choice for projects where durability and a natural aesthetic are desired.

Tung oil finishes are renowned for their ease of application and maintenance. Unlike some finishes that sit on the surface of the wood, tung oil merges with the wood, enhancing both its appearance and longevity.

Over time, it cures by oxidation, forming a solid layer that doesn’t chip or peel. This curing process brings out a warm, rich tone in the wood, which is highly sought after in antique restorations and high-end woodworking projects. Additionally, as it is a natural product, it’s often preferred by those seeking environmentally friendly finishing options.

Benefits of Using Tung Oil

When comparing teak oil vs tung oil, many woodworkers prefer tung oil for its unique ability to enhance wood’s natural character. Tung oil penetrates deeply into wood fibers to create a water-resistant barrier that also allows the wood to breathe. This characteristic is particularly beneficial in preventing wood from cracking and warping, making it a superior choice for wooden items that are exposed to the elements or those that experience frequent changes in humidity.

Another advantage of using tung oil is its non-toxic nature, which makes it safe to use on surfaces that come into contact with food, such as cutting boards and kitchen countertops.

Unlike some finishes that sit atop the wood, tung oil cures to a hard, matte finish that doesn’t peel or flake, offering a durable protection that lasts. Its ease of application and maintenance also adds appeal, as it can be easily touched up over time without the need for sanding or stripping, preserving the wood’s beauty and extending its life.

The use of tung oil can be traced back centuries, particularly in China, where it was used not just for wood protection but also for waterproofing ships. Its natural origin—extracted from the seeds of the tung tree—means it is a renewable resource, adding an eco-friendly appeal to its list of attributes.

For woodworkers looking for a finish that preserves the wood’s character, enhances its durability, and maintains an environmentally conscious approach, tung oil presents an appealing option. The finish it leaves is subtly glossy and reveals the wood’s grain and color with exceptional clarity, which is often a desirable outcome in fine woodworking projects.

As we conclude, remember – TedsWoodworking is your ally in woodworking aspirations. Dive into 16,000+ projects with ease. Your creativity knows no bounds. Happy crafting!

Related Articles

- A Guide to Wood Finishes That Are Food Safe

- Polyurethane vs Polycrylic – Choosing the Right Finish for Your Wood Projects

- 6 Myths About Wood Finishing that Need to Go Away

Ready to start your next project? Join our DIY community to receive tool tips, how-to guides, and exclusive creative insights. Subscribe to the ManMadeDIY newsletter now! Click here to unlock a world of hands-on inspiration.

Frequently Asked Questions (FAQs)

What is the main difference between tung oil and teak oil?

Tung oil is a pure oil derived from the seeds of the tung tree, known for its tough, protective finish that penetrates deep into the wood to enhance durability and water resistance. Teak oil, on the other hand, is not derived from teak wood but is a mixture of oils, including linseed, tung, varnish, and sometimes a bit of urethane for added hardness. It’s called “teak oil” because it’s designed to protect dense woods like teak.

Which oil provides a more durable finish, tung oil or teak oil?

Tung oil provides a more durable finish compared to teak oil. When cured, tung oil creates a hard, water-resistant surface that is highly protective against environmental elements. Teak oil, while offering protection and enhancing the wood’s appearance, may require more frequent reapplications to maintain its effectiveness, especially in outdoor settings.

Can tung oil and teak oil be used on all types of wood?

Both oils can be applied to a variety of woods, but they each excel on different wood types. Tung oil is versatile and can be applied to almost any type of wood, providing a strong, protective finish. It works especially well on dense woods. Teak oil is formulated for dense, oily woods like teak, mahogany, and rosewood, helping to maintain their natural beauty and moisture without causing the wood to darken significantly over time.

How do tung oil and teak oil affect the appearance of the wood?

Tung oil penetrates deep into the wood, creating a matte to satin finish that enhances the natural grain and character of the wood without significantly altering its color. Over time, it can add a warm, amber tone to the wood. Teak oil, while also penetrating, tends to give the wood a slightly glossier finish compared to tung oil and can darken the wood slightly more, enriching its natural colors and grain patterns.

What are the drying times for tung oil versus teak oil?

Tung oil typically has a longer drying time, often requiring 24 to 48 hours between coats, and may take several days to fully cure. Teak oil dries faster, usually within 12 to 24 hours, making the overall finishing process quicker. However, the exact drying times can vary based on environmental conditions and the specific formulation of the oil.

Are tung oil and teak oil eco-friendly and safe for use on surfaces in contact with food?

Pure tung oil is considered eco-friendly and, once fully cured, is safe for surfaces that come into contact with food, making it a popular choice for kitchenware and countertops. Teak oil formulations vary, and while many are low in VOCs (volatile organic compounds) and relatively safe once cured, it’s essential to check the specific product’s safety for food contact. Always follow the manufacturer’s guidelines and allow for full curing before using treated items for food.

How often should I reapply tung oil or teak oil to maintain the finish?

The frequency of reapplication depends on the usage and exposure of the wood. For items or surfaces subjected to heavy use or outdoor elements, tung oil might need reapplication once a year, while teak oil could require reapplication every few months to maintain its protective qualities. Indoor furniture or items not exposed to water or sunlight can go longer between treatments, often several years, depending on the initial application’s durability and the wood’s condition.